Metrology is defined as the science of measurements or the precision of measurements. Even it can be defined as the accuracy of measurements.

The science which is dealing with measurements and their conditions is called measurement science or metrology.

In this article, we will discuss Methods, Standards, and Instruments for Linear Measurements.

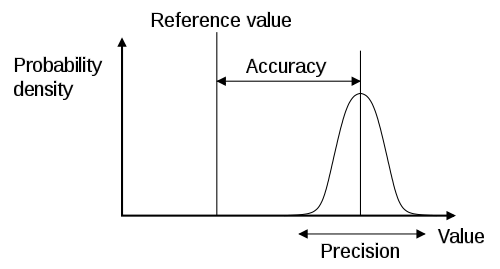

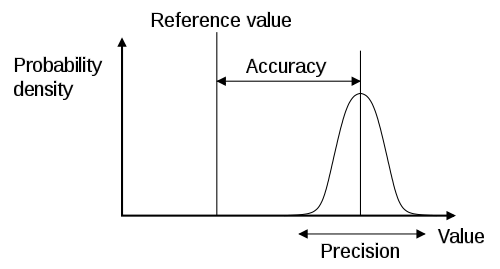

But before that, we should have to know about Precision and Accuracy.

It is the repeatability or reproducibility of measurements.

Whatever the number of times a given dimension is measured by using given measuring equipment if the same dimension is obtained every time called repeatability or reproducibility of measurements.

Whenever only one measuring equipment is involved in the measurement of the dimensions, the Precision is important.

The nearness to the true value is called accuracy.

The precise measurements made by using standard measuring equipment or non-errored measuring equipment is called Accuracy of measurements.

Whenever more than one measuring equipment is involved in measuring dimensions, accuracy is important.

The measurement of lengths, thickness, diameter, and heights including external and internal measurements is called Linear measurement.

They are 3 standards used for Linear Measurements and are as follows:

The explanation is as follows.

The detailed explanation for the Methods of linear measurements is as follows.

If the lines of measuring equipment are coincided with the ends of a measurand, by counting the number of lines in between the coincidence lines and multiplied by one scale division, the dimension of the component will be obtained called line standard measurement.

For Example, Scale, tape, etc.

No.of lines = 95-32 = 63.

L= n*one scale division

= 63*1

= 63

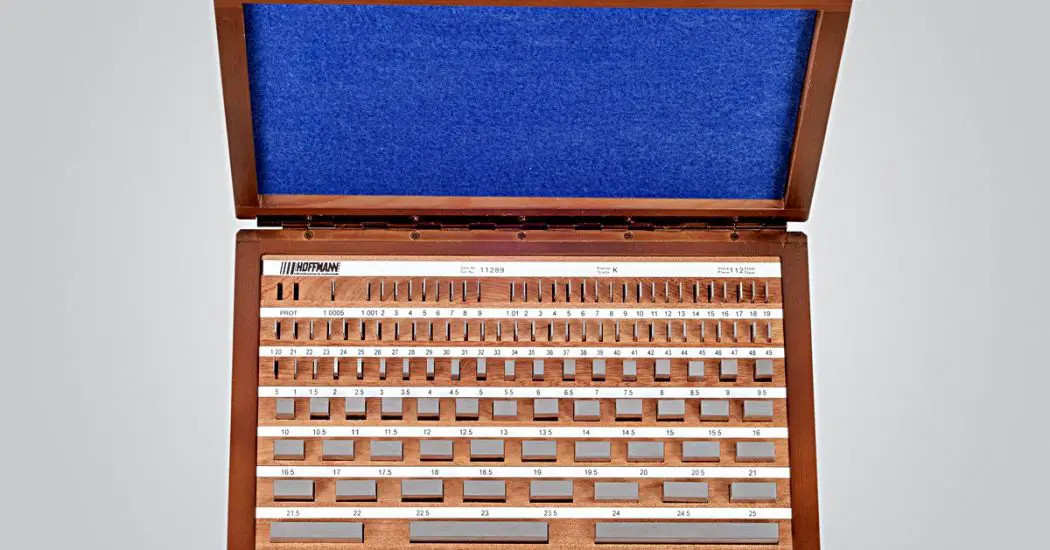

If ends of measuring equipment are coincided with the ends of the measurand and by adding the individual dimensions of the end standards used. The dimensions of the component will be obtained called End Standard Measurement.

For example, Slip gauges, end bars, etc.

If the ends of measuring equipment are coincided with the ends of a measurand and by using the lines if the dimension of the component is obtained called as Line and End standard method of measurement.

For example, Vernier Caliper, Screwgauge, etc.

A Slip gauge is specified by using its height only.

They are made by using high carbon steel as a material.

The top and bottom surfaces of the slip gauge are lapped with other slip gauges so as to construct a given height to measure the angle of the given specimen by sine bar and for that, a final machining operation is to be done on the slip gauges to get a very high degree of surface finish.

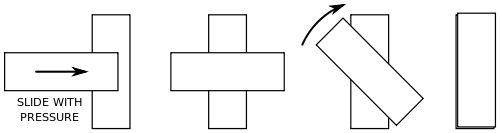

Building a given dimension using more than one slip gauge by forming a temporary bond between the slip gauge surfaces is called the Wringing of slip gauges.

Atoms present on the highly polished surface are more active to share the energy with the other atoms.

Therefore, when two slip gauge surfaces are contacting and placed at 90° and rotated with the application of the little amount of force so that the temporary Bond formation is taking place between the two slip gauge surfaces. This is called as wringing of slip gauges.

The direct measuring instrument is divided into two types.

Therefore, this is the detailed information about the Linear Measurements. If you have any doubts, feel free to ask in the comments section.

Mohammed Shafi is the founder, managing editor, and primary author of Mechanical E-Notes. He is an Assistant Professor (Department of Mechanical Engineering) at the Sreenidhi Institute of Science and Technology. He has a 6 years of vast experience in design, research, and data analysis. Shafi has co-authored two journals 1. Dynamic and Fatigue Analysis on Tillage Equipment 2. Welding Procedure and Testing Analysis on Mixing and Nodulizing Drum.

Before understanding the System of limits fits and tolerances ,you need to have basic knowledge of what is a limit and what is Tolerance? However, I have explained in detail the Types of Fits. You can check it once. In this article, we will discuss on Limits Fits and Tolerance along with their types, tolerance […]

Angular Measuring Instruments are the devices that are used to measure the angle of the given specimens. Types of Angular Measuring Instruments: There are various types of Angular Measurements which are based on various standards, and those are the following: Line Standard Angular Measuring Devices Protractor Universal Bevel Protractors Face Standard Angular Measuring Devices Sine […]

Measuring Instruments plays a vital role in the Engineering Workshop. The Instruments duty is to measure the given specimen according to the given dimensions. So in today's class, we will be discussing on Types of Measuring Instruments and their Uses in Engineering Workshop. In the last class, we had discussed Angular Measurements and Linear Instruments […]

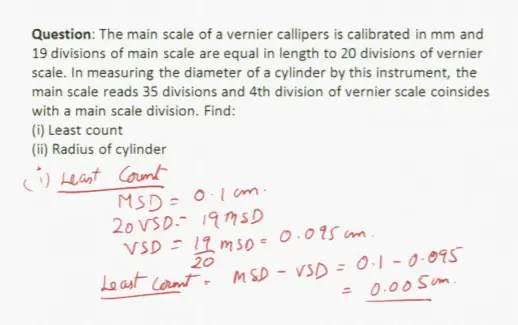

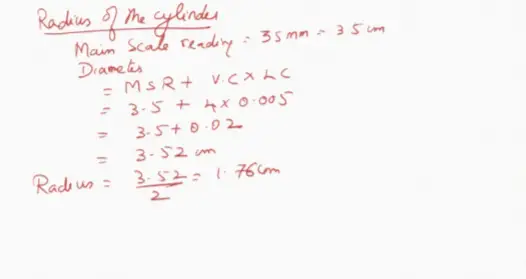

Vernier Caliper is used to measure the dimensions of the given specimen like diameter (Outer Dia and Inner dia), length and depth, etc very accurately that's the reason it is also called as Precision measuring Instrument. In the last class, we had discussed the concepts on Angular Measurements & Linear Measurements and in today's paper, we […]

In the last session, we had discussed Marking and Measuring Tools used in Engineering Workshop. Apart from that, a detailed article on Working of Vernier Caliper was also discussed. But in today's article, we are going to study about Angular Measuring device called as Sine bar. In this paper we are going to cover the topics like Working Principle, Construction, Limitations […]

Fit is defined as the degree of freedom of tightness between the mating parts in an assembly process, it is also defined as the relationship between the hole and the shaft during the Assembly is called Fit. In this article, we are going to discuss different types of Fits in a detailed way. The various parameters that can be included […]